On Monday, March 24, 2025, as announced by the American company GE Aerospace (part of General Electric), a ceremony was held in Środa Śląska, Lower Silesian Voivodeship, to mark the opening of the XEOS Aircraft Engine Maintenance, Repair, And Overhaul Center, operated by a 75/25 joint venture between GE Aerospace and Germany’s Lufthansa Technik.

On October 30, 2024, GE Aerospace announced that it would invest approximately 30 million USD in the aircraft engine Maintenance, Repair & Overhaul (MRO) facility in Środa Śląska to meet the growing demand for services related to GE Aerospace and CFM International engines. CFM International is a 50/50 joint venture between GE Aerospace and Safran Aircraft Engines. These engines power today’s most popular single-aisle aircraft, including the CFM LEAP-1A for the Airbus A320neo family and the CFM LEAP-1B for the Boeing 737 MAX.

“The inauguration of this facility highlights GE Aerospace’s dedication to meeting the MRO ramp for CFM LEAP engines and our commitment to Poland,” said Alan Kelly, general manager of LEAP services at GE Aerospace. “Celebrating 30 years in Poland, GE Aerospace now has over 2,000 employees across six facilities, partnerships with eight local universities, and more than 1,000 local suppliers. We are also focused on developing a skilled aerospace workforce in Poland, including investing in young talent through our Next Engineers program in Warsaw.”

XEOS is currently performing overhauls of LEAP-1B engines and supporting core module work and testing for LEAP-1A engines. The facility also plans to begin testing LEAP-1B engines in the coming months, while simultaneously expanding its repair and overhaul capabilities.

“Two months ago, we proudly announced that LOT Polish Airlines had selected Lufthansa Technik for the maintenance of its CFM LEAP-1B engines,” said Christian Seitler, Senior Director, New Engine Types at Lufthansa Technik, which is also a CFM-licensed Premier MRO provider for LEAP-1A and LEAP-1B engines. “It’s fitting that, through our XEOS joint venture with GE Aerospace, we have inducted LOT’s first engine right here in Poland. This state-of-the-art facility supplements our existing LEAP engine shop in Hamburg.”

On January 23 of this year, Lufthansa Technik and LOT Polish Airlines signed an agreement for support of CFM LEAP-1B engines. The Polish national carrier currently operates a fleet of 18 Boeing 737 MAX 8 aircraft, with an additional 13 on order — bringing the total to 62 CFM LEAP-1B engines, plus spare units.

“We are delighted to witness our CFM LEAP-1B engines being serviced by our compatriots at XEOS,” said Maciej Maciejewicz, Head of Powerplant at LOT Polish Airlines. “This newly adjusted, state-of-the-art facility, coupled with a highly skilled workforce, presents significant potential benefits not only for our airline but also for the burgeoning aerospace sector in Poland.”

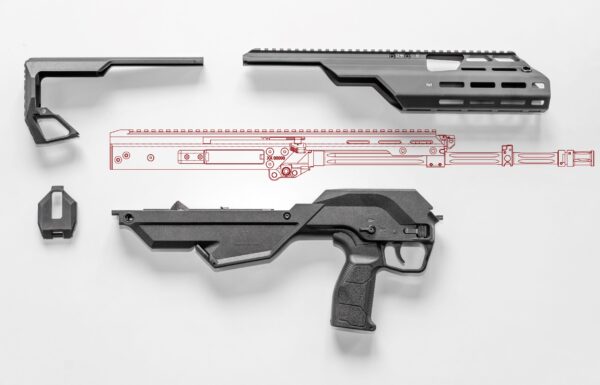

XEOS is a 35,000-square-meter facility that includes a prep hall for engine inspection, a main hall for engine and core module assembly and disassembly, a modern cleaning and inspection line, a set of repair stations, a hands-on training center, and an advanced test cell. The facility incorporates the latest best practices in design and operations, based on Lean methodology and GE Aerospace’s proprietary operating system, FLIGHT DECK.

“The XEOS workforce is 250 strong and growing as we build our capacity,” said Robert Burton, managing director of XEOS. “With training engines on site, we’re able to staff, train, and build capability quickly – to develop a talented workforce here in the Wrocław region.”

GE Aerospace technologies have powered LOT Polish Airlines aircraft for over 25 years. This includes CFM56-3, CFM56-7B, and LEAP-1B engines for the Boeing 737 Classic, 737 Next Generation, and 737 MAX respectively, as well as CF34 engines for the Embraer E-Jet family.

GE Aerospace also supports the Polish Air Force by supplying engines for several types of aircraft and helicopters. On January 8, 2025, the company received an order to produce 210 T700-GE-701D turboshaft engines for Poland’s future fleet of 96 Boeing AH-64E Apache Guardian attack helicopters.

It is also worth noting that the Środa Śląska facility has been under development since 2017. After two years and an investment of approximately 1 billion PLN, the center held its initial opening as an MRO hub for GEnx-2B and GE9X engines powering wide-body Boeing 747-8 and 777 aircraft. The site initially employed around 300 people, with plans to scale up to 500–600. Its early servicing capacity was expected to be around 20 engines per year, with a projected increase to over 200 by 2023. However, the COVID-19 pandemic triggered a crisis in the aviation industry, leading to the decision to place the facility in hibernation and reduce the workforce to around 60 employees.

https://twitter.com/GE_Aerospace/status/1904150345355526427