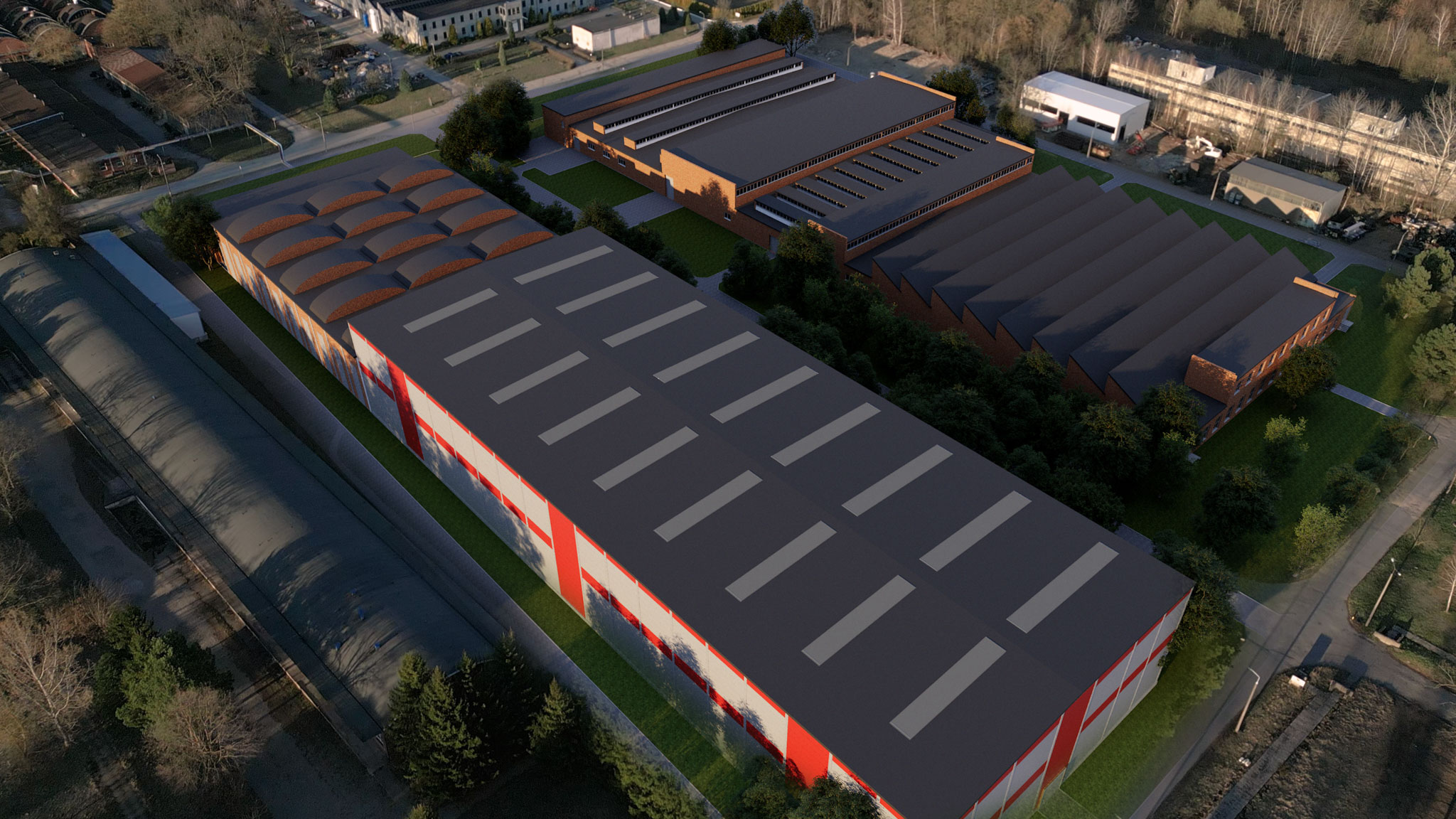

The investment, financed by the Capital Investment Fund, includes expanding the production hall to 9,000 square meters, modernizing existing facilities, and installing new production lines. Mesko, a company owned by Polish Armaments Group (PGZ), remains the only manufacturer in the country of 155 mm shell bodies and bases (Poland: First Thousands of 155 mm Shells Roll Off Mesko Production Lines – Target: 150,000 Rounds Per Year).

From Billet to Shell Body

The process of producing the ‘steel skin’ of an artillery shell in Kraśnik begins with deliveries of square-section steel bars from a domestic steel mill. These massive billets of metal first go to cutting stations, where they are divided into precisely measured sections. Next comes the heavy work of hydraulic presses, steel heated to the proper temperature, is hot-formed into the shape of the future shell body. In the following stages, the semi-finished products pass through CNC lathes that give them dimensional precision, after which they go into normalization furnaces. The heart of the process is hardening, carried out in specialized, robotized furnaces that ensure uniformity and repeatability of strength parameters (Expansion of Mesko’s plant in Kraśnik).

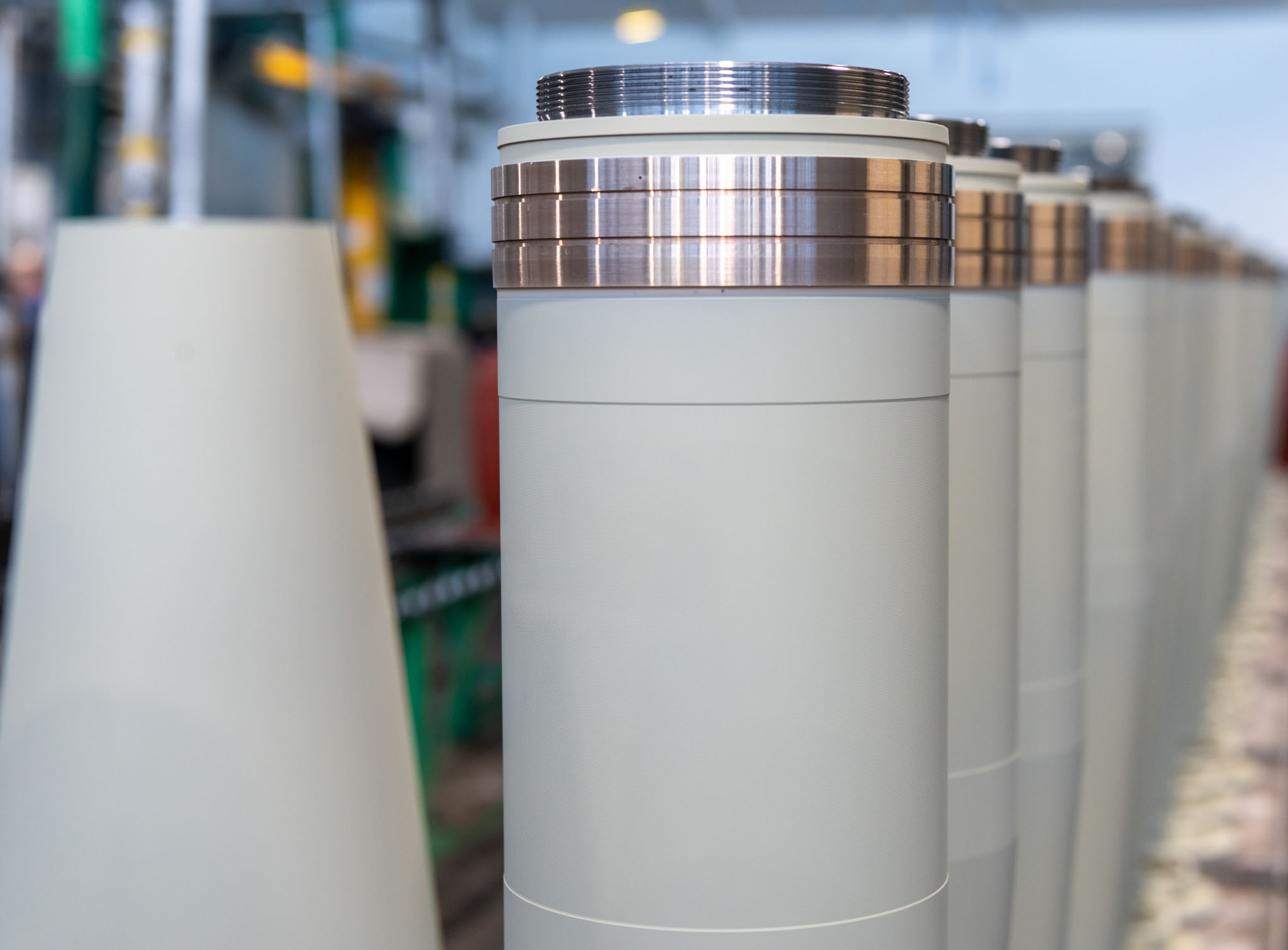

Precision and details

After heat treatment, the shell bodies are shot-blasted and then finish-turned. Next, a driving band is welded on, a key element for proper guidance of the projectile in the barrel. That is followed by ultrasonic cleaning, painting/coating, and marking. Each unit undergoes rigorous quality control, from dimensional measurements to tests of surface condition, hardness, strength, and material structure. Only then, packaged and labeled, does it leave the hall in Kraśnik to go to other facilities of the Polish Armaments Group, where it will ultimately become a fully finished 155 mm artillery projectile.

Rearmament on an Accelerated Schedule

“After the investment is completed in 2027, the Kraśnik plant will reach a production capacity of up to 150,000 shell bodies per year. “This is a project of strategic importance for the country’s security. Our goal is to supply the Polish Army with ammunition in quantities that meet the challenges of the modern battlefield, and to do so entirely based on the Polish supply chain,” emphasizes Mesko CEO Renata Gruszczyńska.”

Press release

See also:

- BAE Systems Partners with Polish Armaments Group on 155 mm Ammunition Production

- Polish Government to Increase Funding for PGZ Group and Partnering Companies and Institutes

- Eurenco and Mesko strengthen strategic partnershipwith long-term energetic nitrocellulose supply agreement

- Polish Armaments Group with a concept for building three ammunition factories

- 2.4 Billion PLN for the Polish Armaments Group to Support 155 mm Ammunition Production

- Project 400: Polish company Mesko has increased its small-caliber ammunition production capacity fivefold

- Mesko is implementing another project under the European Defence Agency