The GROTowisko conference had a two-day format, which initially included presentations, followed by practical familiarization with the weapons, combined with competitions. The first part, consisting of lectures, took place at the Brigadier General H. Cepa Communication and Information Technology Training Center Club in Zegrze.

The conference was opened and attended until the very end by Brigadier General Krzysztof Stańczyk, commander of the Territorial Defence Forces (WOT). It is the WOT that serve as the expert institution (formerly the manager) responsible for the modular individual weapon, so it is not surprising that this new branch of the armed forces organized the event.

The event also had support from the Ministry of National Defense. During the opening, a letter to the participants, signed by the Minister of National Defense Władysław Kosiniak-Kamysz, was read. In the letter, he emphasized that the Grot is a Polish weapon, entirely designed and produced domestically. He also highlighted the aspect of developing the design with and for the users.

Conclusions from the use so far

The conclusions drawn from the use of the weapon in the military so far were presented first. Attention was drawn to potential improvements, which included the introduction of better mechanical sighting devices. The current folding ones were considered an emergency solution from the beginning.

Photo: Territorial Defence Force

Photo: Territorial Defence Force

It was also suggested to reinforce the magazine lips by introducing metal components, which would extend their durability and ensure that the bolt is held in the rear position each time after all rounds have been fired.

The military also recommended considering a return to a trigger mechanism with the capability of firing 3-round bursts, as was the case with the Beryl family of rifles. This would allow for more economical use of ammunition, especially in stressful situations.

Major Mateusz Jastrzębski, in his presentation, also referred to the use of an ultrasonic cleaner for better and more efficient cleaning of weapon assemblies. It was noted that including such a maintenance method in the manual would be a good idea, which would additionally facilitate the seamless purchase of similar devices for the military.

Grot A3

The main highlight of Grotowisko was a presentation by Seweryn Figurski, the CEO of Fabryka Broni Łucznik-Radom (manufacturer of Grot), combined with the premiere of an improved version of the Grot rifle, provisionally named A3. As Seweryn Figurski informed MILMAG Editorial Staff, “The Grot A3 is a proposal from the company, and its configuration may change during consultations with the Polish Armed Forces.”

Seweryn Figurski during the Grotowisko conference / Photo: FB Łucznik-Radom

As a model in the presentation, a standard rifle with a 406 mm/16 inch barrel, which has been introduced into the armament of the Polish Armed Forces, was shown. After implementation of the proposed modifications, the weight of the standard variant will be reduced from 3.7 to 3.4 kg. However, the live demonstration model featured a shortened barrel of 368 mm/14.5 inches, as the suggested standard for the Polish Armed Forces.

A new feature in the A3 variant may be the extensive use of the Tenifer (ferritic nitrocarburization) process on up to 30 parts of the weapon. This is a technique that strengthens the outer layer of metal to improve its hardness, wear resistance, and corrosion resistance. Tenifer treatment may include the bolt carrier, gas chamber with regulator, barrel extension, charging handle assembly, and parts of the trigger mechanism.

From the outside, the Grot A3 was distinguished by the use of a butt stock housing adapted for the AR standard, allowing for a longer extension range of 30-50 mm. Taller shooters, who were hindered by the length limitations of the original Grot stock, had complained about this issue. However, the adapter still allows the stock to be folded to the side, which is impossible in AR-based designs.

The Grot A3 was presented by Fabryka Broni during the Grotowisko 2024 conference. The package of changes is a proposal from the Radom-based company, and the final configuration of the new variant may be subject to changes during consultations with users.

The Grot A3 was presented by Fabryka Broni during the Grotowisko 2024 conference. The package of changes is a proposal from the Radom-based company, and the final configuration of the new variant may be subject to changes during consultations with users.

In the rifle presented at Grotowisko, two commercial folded stocks were used. However, if such a solution is chosen by the Polish Armed Forces, Fabryka Broni will develop its own stock designs. These may end being equipped, like the original from Radom, with a cheek rest.

Another noticeable change was a different handguard with a reduced and slimmer profile, which makes the weapon easier to grip, especially in a standing position. The rigidity of the connection between the handguard bridge and the receiver of the weapon was also reinforced by introducing a stabilizing lug.

This will allow for the mounting of the front sight base on the bridge and the use of the weapon without losing the aiming point, which could happen with the original design. Because of that issue, in the Grot C16A2, the front sight was usually mounted not on the bridge, but slightly earlier, at the end of the receiver. This, in turn, reduced the distance between the front sight and the rear sight, which decreased aiming precision.

Fabryka Broni also proposes a slight change to the receiver cover in the A3. Primarily, this involves reducing its weight, partly through a different design of the rails of the universal accessory interface on the top. The same approach applies to the handguard cover.

The use of a slimmer (lower) handguard was also made possible by changing the barrel module. A completely new gas regulator assembly was introduced. It was designed without the six vent holes in the lower part. As a result, during firing, the weapon does not blow hot propellant gases and dirty particles of unburned propellant onto the hand on the handguard.

These are not the only changes in this area. The Grot A3 features a new gas regulator with a latch that prevents accidental disassembly of this component due to impact or snagging on a carrying strap (although the introduction of a longer handguard has already mitigated this issue).

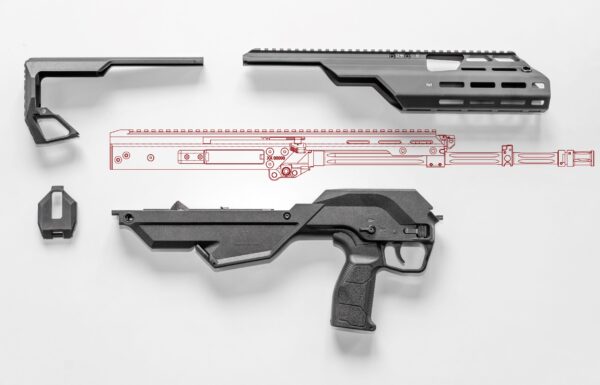

Grot A3 partially disassembled, showing the new gas system

Grot A3 partially disassembled, showing the new gas system

Moreover, the gas piston and the operating rod have also been redesigned, integrating these two components and allowing them to be pushed forward after the regulator is removed. Previously, cleaning the piston rod required unscrewing the entire barrel assembly. Although this was not a significant issue since the rod does not need frequent maintenance, the new solution facilitates proper care of the weapon. The only element that raises some controversy is the spring, which is removed along with the piston and rod.

These are not the only changes in the barrel area. At the military’s request, a threaded muzzle device (1/2-28 UNEF) may be used instead of the previously pinned one. This has its advantages – the ability to switch to commercial solutions (better flash suppression or the ability to attach or mount sound suppressors) – but also its drawbacks – the inability to mount a bayonet.

The bayonet was intended to be mounted on the standard rifle with a 406 mm barrel. It was not proposed for specialized versions, including the shortened variant of the weapon. The Grot A3, shown at Grotowisko and proposed to the military, has a 368 mm/14.5 inch barrel. This is an intermediate length between the accepted 406 mm for the standard rifle and 267 mm for the carbine (nominally, the barrel length of the Grot C10 is 10 inches, but in reality, it is longer, measuring 10.5 inches). It is uncertain how the Polish Armed Forces will respond to such a solution. However, there are armies (e.g., the American or Israeli) for which a design with a barrel around 350 mm is standard.

Less noticeable at first glance but very significant improvements to the weapon were hidden inside. Fabryka Broni proposes the introduction of a redesigned charging handle with an internally mounted catch and a split handle. All of this, along with a slight modification to the receiver reducing the gap through which the handle moves, is intended to allow for better sealing of the weapon’s interior.

Grot A3: changes proposed by Fabrykę Broni

Grot A3: changes proposed by Fabrykę Broni

Fabryka Broni also proposes changes to the bolt carrier in the A3 variant. The most important modifications include slightly raising it, changing the shape of the cutout for the cam pin, and adding a cover for the charging handle catch. Combined with the changes to the charging handle, this is intended to seal the interior of the receiver and eliminate jams that could be caused by contaminants.

The problem is more theoretical than practical. It has not been reported by actual military users (including those using the C16A1+ variant in the Ukrainian conflict), but was only identified by testers who covered the rifle with aquarium sand. However, the manufacturer prefers to err on the side of caution.

Additionally, a technological change in the method of mounting the bolt carrier insert is also suggested. Normally, it is cut from the top to perform the operation of cutting the unlocking cam and then sealed. Instead of welding it, Łucznik also proposes the option of mounting the insert with pins. This proposal was presented at Grotowisko.

It is worth noting that cracks in the weld of the insert gave users who were not very familiar with the weapon’s design the impression that the entire component was damaged. This had nothing to do with the actual functioning of the weapon and did not affect safety. The proposed changes are cosmetic in nature. However, in a world where minor details are scrutinized and used to judge the apparent quality of the weapon, this is important for the manufacturer’s image.

For the user, the proposed design change to the bolt assembly in the Grot A3 may be more significant. The diameter of the ejector roll pin has been increased, as this component was wearing out faster than anticipated.

From an operational standpoint, the cam pin has also been extended. This was done to prevent the issue of inserting the bolt in the unlocked position during reassembly. Although this only occurred with inexperienced users who had not familiarized themselves with the weapon’s manual, the modification will allow for the complete elimination of this problem.

Some changes have also been made to the trigger housing. A modification of the magazine well cutout is proposed to allow for the mounting of certain widely-used commercial magazines (such as the Magpul PMAG GEN3) with a body design different from the standard. As you can see, Fabryka Broni is following a trend that is more relevant to civilian users than military ones.

More important change for the trigger housing area is the material and manufacturing technology of the bolt catch lever, which releases the bolt assembly from the rear position. Previously, it was made of plastic; now it will be made of aluminum alloy. There were instances where the carrying strap would get caught between the cutouts of the housing and the catch, acting as a lever and causing the less durable plastic to break. It is worth noting that similar commercial aluminum solutions are produced by the Polish company DEFTAR.

Certainly, users will be pleased with another proposed change in the A3, which is the increase in the diameter of the bolt catch pin to ensure greater reliability in holding the moving assembly in the rear position after all rounds have been fired from the magazine. There were some issues with this, particularly in the older versions of the Grot A0 and A1.

The changes also include a simplification of the trigger mechanism. The military also requested changes to the design of the safety lever, similar to those in other armies. In simpler terms, this involves modifying the safety level combined with the fire mode selector to increase the angle between the semi-automatic and fully automatic settings.

Until now, the change in position of the selector lever between each setting was 45 degrees. In the Grot A3, Fabryka Broni proposes two options. Either a consistent 90-degree travel between the safety and all fire modes, or a 45-degree travel between the safety and semi-automatic mode, followed by a 90-degree travel (a total of 135 degrees from the safe position) to switch to fully automatic mode.

This is intended to increase the safety of handling the weapon and prevent the selector from being switched directly to fully automatic mode under stress. Transitioning to this firing mode should be a deliberate decision made after careful consideration, hence the difference in the selector lever settings.

Since users complained about the screws securing the case deflector and ejection port cover, the manufacturer’s proposal is to replace the M3 countersunk screws with a 2-mm hex socket with M3 pan head screws with a 2.5-mm hex socket. This will make screwing and unscrewing easier and reduce the possibility of damaging the screws during incorrect manipulations. This may seem cosmetic, but it is important for military weapons.

In addition to the weapon itself, FB Łucznik proposes introducing new accessories for the Grot A3. Most notably, this includes a handguard assembly with a QD sling socket in the front part, as well as a QD sling socket assembly adapted to M-LOK mounting slots and the use of a rotation limiter in the QD sling attachment. This will make the use of the sling more convenient. The soldier will be able to mount the socket at a distance suited to their needs. The last element will also allow for better control of the sling’s position.

Seweryn Figurski also stated that work on the A3 changes began at the stage of introducing the A2 version to the military. Furthermore, he informed that the signed contract for the weapon allows for modifications to be made to newly ordered rifles. Thus, not all of the 256,000 Grots covered by the contract have to be delivered to soldiers in the A2 version.

Fabryka Broni continues to work on further improvements and variants of the Grot. To reduce the weight of the design, a prototype of the rifle with a barrel that cannot be removed in field conditions has already been created. It will still be replaceable, but only with the use of a special tool in an armorer’s workshop.

Grot – History, Usage, Cleaning

A very interesting presentation during Grotowisko was given by editor Michał Sitarski. Although its content diverged from the title listed in the program, the speaker first presented the origins of the 5.56 mm Modular Small Arms System program, in which he had been involved almost from the very beginning. He then dispelled myths about the Grot’s origins, which was allegedly a copy of some foreign designs, before moving on to the real highlight of his presentation.

Michał Sitarski presentation

Michał Sitarski presentation

He presented comparative tests conducted within the Territorial Defense Forces on cleaning and maintenance methods for the weapon, in accordance with military standards and “civilian style,” using commercial products.

The photos were startling, showing the exact same weapon during one week of training, cleaned and maintained “military-style,” compared to the same procedures performed in another week using commercially available solutions. In the first case, the weapon showed signs of rust and improperly maintained components, while in the second case, it gleamed with cleanliness.

The test indicates that the Polish Armed Forces should immediately reconsider the procedures and materials used for cleaning and maintaining the Grot. The test shows that most of the initial problems, aside from the poor knowledge of the design by trainers and users themselves, stemmed from improperly chosen procedures and the use of outdated cleaning tools. This task is urgent!

Michał Sitarski also shared military experiences from the same unit regarding the use of solid lubricants for weapons. Suddenly, physically weaker individuals no longer had problems with charging the bolt carrier! This is an important lesson that, in addition to the firearm’s design, good quality products should also be used for its maintenance. Even the best engine will perform poorly if the user fills it with poor-quality fuel and uses substandard lubricants and oils (GROT C16A2 in the Polish Armed Forces).

Analysis of the Small Arms Shooting Program

Another highlight of Grotowisko was the analysis of the new “Small Arms Shooting Program” conducted by Lieutenant Bartosz Florczak, focusing on changes in shooting training methodology using the Grot rifle as an example.

The speaker is a well-known senior specialist in fire training for the Territorial Defence Forces, whose presence was warmly welcomed by the soldiers attending the conference. He focused on presenting the upcoming shooting program, which is finally set to become a unified training foundation, identical for all units of the Polish Armed Forces.

He emphasized the purpose of introducing greater flexibility in training, not only with the strong hand but also with the weak hand. He highlighted the importance of shooting from all stances – standing, kneeling, and prone. A revolutionary aspect of the training is to teach soldiers the proper configuration of their equipment before starting sessions at the shooting range, including the placement of pouches and adjustment of the sling.

He strongly emphasized the role of introducing uniform teaching standards by instructors in the Polish Armed Forces. Until now, there has been considerable variation, especially in the Territorial Defence Forces, where training groups operated according to the diverse experiences and methodologies of their members. Therefore, the goal is also to implement optimal training and methodological solutions.

Lieutenant Florczak highlighted the aspect of improving accuracy in firing both the Grot rifle and – since it is to be a common weapon in the military – also the semi-automatic pistol. He also emphasized the aspect of safety, which involves mastering the handling and use of weapons in various situations.

The foundations of the new shooting training system will include: selection and proper configuration of equipment, operation in the “workspace,” correct checking, loading, and unloading of weapons, threat identification, building and assuming the correct shooting stance, aligning sights, trigger control, target, weapon, and environment control, various methods of magazine exchange, as well as clearing typical and atypical malfunctions.

Somewhat surprisingly, based on experiences from Ukraine, the primary stance is to be standing. Only in the next stage will kneeling be introduced, followed by prone and turns. This may be due to the specifics of light infantry, but during an armed conflict, the focus on basic stances might need to be reordered.

At the end of his lecture, the instructor also highlighted potential weapon modifications, some already addressed in the Grot A3 proposal, but some quite surprising. The military personnel expressed a desire to lengthen the sling, whereas in the A2 variant, the request had been to shorten it. The issue of introducing night sights was also raised again.

The proposed change in barrel length to 305 mm/12 inches by the training staff sparked discussion. This change was intended to make the weapon more handy. It seems that the experience of shooting at targets does not necessarily translate to the understanding that on the battlefield, alongside the convenient handling of a shorter and lighter rifle, one must also have sufficient bullet energy on target, which such a barrel length does not provide.

At the end, Colonel Mirosław Zahor, a representative of the Military University of Technology and one of the fathers of the MSBS-5.56, supplemented the discussion. He confirmed that based on research conducted at the Military University of Technology, maintaining proper ballistics and energy for a standard rifle requires a barrel with a minimum length of 350 mm (just under 14 inches), but no shorter.

A few words regarding Tytan program

The next speaker was Colonel Karol Grudziński, head of the Tytan program division from the Armament Agency of the Ministry of National Defense. He provided a comprehensive overview of the system environment of the 5.56-mm Grot rifle in the context of the Polish soldier of the future.

The Advanced Individual Combat System Tytan is divided into seven subsystems: combat uniforms, individual equipment carrying, ballistic protection (including the HBT-02 combat helmet and KBT-01 ballistic-tactical vest), protection against weapons of mass destruction, operations management (C4I), observation and reconnaissance, and weaponry.

Within the latter subsystem, there will be the Grot carbine and carbine-grenade launcher, in both classic and bullpup variants, the Vis 100 pistol, and a range of combat means, including new 40 mm x 46SR ammunition for the single-shot grenade launcher, 5.56 mm x 45 ammunition with an armor-piercing tungsten-core bullet, and a family of hand grenades (universal fragmentation, thermobaric, smoke signaling in yellow, red, and blue, and training grenades).

He also highlighted the development of a Polish laser designator, illuminator, and target illuminator, as well as a range of collimator sights. A representative of the WB Group present at the conference expanded on the topic of personal communication within the Tytan program, emphasizing the integral equipment of radio sets with hearing protectors and a communication headset.

Grot 762N i Grot PC Rifles

The last speaker was Paweł Madej, the Director of Development at Fabryka Broni. He briefly described the development of the 5.56 mm Modular Small Arms family. He focused on two designs – the 7.62 mm Grot 762N semi-automatic rifle and the 5.56 mm Grot C20PC semi-automatic rifle with enhanced accuracy (the Border Guard is receiving the first Grot 7.62N rifles).

The first ordered Grot 762N rifles, chambered for 7.62 mm x 51 NATO ammunition, are set to be delivered to selected units of the Polish Armed Forces in July 2024. This rifle is intended not only to replace the SWD/SWD-M semi-automatic sniper rifles but also to provide a weapon with greater range and firepower for elite units.

Therefore, the Grot 762N is available in two versions: one with a 406 mm/16-inch barrel for airmobile forces as a precision weapon, and another with a 508 mm/20-inch barrel as a sniper rifle. The first version features a retractable and foldable AR-standard side stock, while the second version comes with a fixed, adjustable stock.

5.56-mm Grot C20PC / Photo: Remigiusz Wilk

5.56-mm Grot C20PC / Photo: Remigiusz Wilk

An interesting highlight was the premiere of the Grot C20PC sniper rifle, where “PC” stands for “Podwyższona Celność” (Enhanced Accuracy). This is the working name of the weapon, designed, manufactured, and tested as part of the development project no. O ROB 0034 03 001 (RAWAT). The weapon, chambered for 5.56 mm x 45 ammunition, features a precision heavy barrel with a length of 508 mm and an improved trigger mechanism. It fires in semi-automatic mode. The design is intended to allow for accurate shooting at targets up to 600 meters.

The carbine weighs 4 kg, is equipped with a commercial AR-standard stock, and is to be fitted with an optical sight.