MILMAG: It is a pleasure to be with you, Mr. Gevorkyan, here at the MSPO 2025. Could you please tell us, our viewers, our readers, a little bit about your company, about your origins? As I understand, you were established in Slovakia in 1996, and you have a background as a military engineer. Could you please tell us a little bit about the beginnings?

Dipl. Ing. Artur Gevorkyan: So, I have military education, I am an engineer for the aircraft industry, and my specialization is materials, mainly composite materials, and powder metallurgy is part of composite materials. And moreover, my father has the same education, and he was one of the biggest experts in the former Soviet Union countries. It was logical when I left the army in the 90s to decide to continue my father’s profession. I am Armenian originally, but I left Armenia. It was 91. Because at that time Moscow switched off electricity and gas, it was not possible to operate some industrial companies in Armenia. So I left Armenia and established a powder metallurgy private entity in Ukraine in Kharkiv city. And later on, in five years, I started getting more requests from Europe and decided it was necessary to be present in Europe and establish a company in Slovakia, because it was easy, it was close to Ukraine, and easy to organize. By the way, my first customers were from Poland, from Sosnowiec, it was Silma, a small motor producer, and from Katowice, it was Magneti Marelli. And since then, we are in Slovakia.

Dipl. Ing. Artur Gevorkyan

Dipl. Ing. Artur Gevorkyan

MILMAG: Could you please elaborate a little bit more about your vision of being more of a supplier, as you are writing on your website, of being a solution provider?

A.G.: We have a very hard history with our company, because I was an immigrant, and, let’s say, all the nice places on the market were already occupied. So, in the beginning, and by beginning I mean the first twenty years, we received only absolutely crazy projects, which were refused already by our competitors from Germany, from Spain, from Italy, and those situations–we need something quick!–they were very very hard, and gave rise to all those crazy problems we promised we would solve, and we really solved them. I know that throughout our history we only had two unsuccessful projects–to give you an idea, yearly we produce a hundred to two hundred projects. This is huge, this is a crazy huge amount, and (only) two were unsuccessful, unfortunately. This generates a (specific) culture in our company, this gives real talents, this gives a chance for those talents for a realization independent of nationality, education, previous experience. We give them a chance to realize their dreams and change their lives to reach the level they wish for.

MILMAG: As I did the research, you mentioned in one interview a few years ago that you haven’t lost a single customer in twenty five years. How is that possible?

A.G.:: This is no big secret. We really work with our first customer, we really produce our first part, moreover the reason is, from our side, this is the result of our development, so we generate this parts, and year by year, we also learn to do this parts better, more cost-effective, so our customers don’t need to go to somebody’s else, to have, I don’t know, five percent better price than our. At the same time we generate next projects, we work on next projects, developments with the same customers, so more I can say our customers, our American or European customers, they protect us from the copies of our potential asian competitors, because they know we need to develop them together in their Sweden headquarters or American headquarters and don’t want to lose us as a partner.

MILMAG: Moving a little bit towards MSPO, where we are now, and Poland. What is the importance of the Polish market for you, what is your strategy, why are you taking part in MSPO?

A.G.:: This is a very personal question, because my grandmother was, how to say it in English? She was raised in a Polish family. After (Armenian) genocide, Polish doctor, who lost two babies because of illness, took her in. Until she was sixteen or seventeen, she was with his family, Polish family. All my life, we heard warm words from our parents about Polish culture, Polish family culture, so this is a very personal question and for me, Poland is a part of my family. When I am here, I don’t feel very immigrant. Even when I am at home, speaking with my mother – “oh, you are going to Poland!” This is very-very important when my immigrant ties are there. My personal opinion, and from this exhibition of all of us – Slovak, Czech, Ukrainian, Belarusian – feeling is the same. Polish people are really commercial(-minded), very active, and generally I think that the Polish economy will grow, and I believe that Polish military industry, including suppliers, supplier base, will grow as well. We already work with several Polish companies, so I already have, in Poland, more military customers than in Slovakia.

MILMAG: It is a pleasure to hear. I haven’t actually expected a family story here, and I hope your grandmother and mother will visit here, and that they will feel at home. However, you mentioned that Polish industry and the Polish economy is growing, and we are at the MSPO, a military expo. What actually is your offer, and how do you perceive the Polish market regarding defense and defense manufacturing?

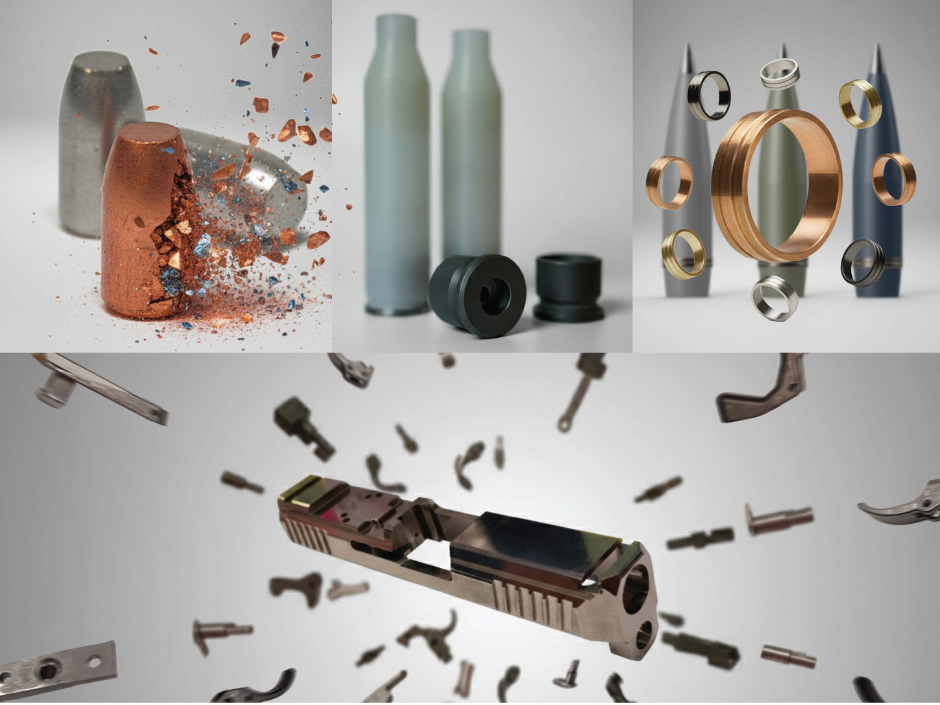

A.G.:: I think it’s important to say that what you present at this exhibition, it’s not a product, it’s a solution. We present completely new solutions for munitions production, we present new solutions for firearms producers, for pistols, rifles. What we offer, on one side, we offer technical solutions, on the other side, we offer immediate capability. If we receive, for example, an order for a complete model, in six-eight weeks we can deliver millions of those parts. And what else is very important, I must say that we are a public company. We are on Prague’s exchange, and our next step will be dual listing on the Warsaw stock exchange.

MILMAG: That’s huge.

A.G.:: Yes, we´ll also be present close to Warsaw.

MILMAG: Yes, I was going to ask next about if you want to establish some presence in Poland, but I think you have already answered that.

A.G.:: Yes, and moreover, we have our representation already in Poland. It will be discussed in more detail during the board meeting in Slovakia, but I am sure we will open trading and development, mainly development, engineering offices in Poland, that will be closer to our customers.

MILMAG: Absolutely. Do you plan to focus on, lets say big industrial customers, like defense companies, or are you open to small manufacturers, such as firearm accessory manufacturers, designers?

A.G.:: First of all, it depends – our industry is now growing, but we are still present in Poland in the automotive industry market, locking industry, welding machines. We have customers from really-really different industries. Because I remember our company history we are forever open to new projects. When we see somebody has an idea, we want to see this fire inside people, the owner of a small company when he develops something, and he trusts, and works really-really hard. In this case, we can – in difference to our competitors, we can produce even a hundred pieces per year only to support those guys who develop the initial stages.

MILMAG: What are the technologies that you present here at the MSPO? I mean, obviously, powder metallurgy, but do you have any special, specific technologies, products in mind that you would like to put the spotlight on?

A.G.:: Now, powder metallurgy is a big range of technologies, four different technologies we could say. There is powder compacting and sintering – what we call classical sintering technology. We present this technology here, mainly for munitions production. Secondly, we have metal injection molding, and here we are speaking about many-many firearm parts, plus we have 3D printing, but this is mainly for prototyping. What is very important for our company in Slovakia, we have a very big CNC production department and we, in difference from almost all our competitors, we deliver finished goods for our customers. They never need to make some additional work on those parts, galvanizing, heat treatment, machining, we are 100% responsible for our product, and they only need to assemble. Moreover, if they wish, we can make some preassembling or partial assembling, completely with the parts we received from them. This is also possible and also a big advantage.

Photos: GEVORKYAN, a.s.

Photos: GEVORKYAN, a.s.

MILMAG: Absolutely, could you please, tell us what standards, special NATO standards, industrial standards you use that respond to the military market?

A.G.:: To avoid it (going through) – it would be a huge list of norms – I can say that from the hardest industry – automotive, we have all the certifications, including certifications for development. This is very important, again, we are not only producers, we are development suppliers for our customers. Plus, additionally we have certification for cybernetic safety and certifications for military, but also for medical industry, because some of our products have such applications they also need medical certification. So, unfortunately for our Quality department, we are forcing all that package.

MILMAG: But that is important for the customer.

A.G.:: That is important for the customer, and I must say, those are not unnecessary things, those norms and certifications, because in the end, they help develop the business in the right way, and avoid mistakes. I am a majority owner of this company, and for me it is personally important to avoid huge disasters, problems, and certifications help.

MILMAG: Do you anticipate or already see increased demand from defense and security sectors, especially in the current geopolitical situation, war in Ukraine?

A.G.:: Sure, I can say that, before, like five-six years ago, the defense industry made up a few percent of our portfolio. Now, these new projects we received, is around one-fourth of our portfolio, which means that it already started (to be) intense. This is a huge increase, maybe ten times.

MILMAG: Do you have any development plans for military-related products, services, or products and services for the civilian shooting market, shooting sports?

A.G.:: Yes, I must say shooting sports was the first, we started with Canada, we started with the Czech Republic, in Slovakia, thanks to shooting sports we started to be known to the firearms producers. And now we work for – many times it’s the same company for both sport and the military. Now they opened for us doors elsewhere for defense application, not only for sport, but for defense. Five-ten years ago there was enough manufacturing capability everywhere, but now it starts being critical.

MILMAG: Have you already completed any contracts for Polish defence industry?

A.G.:: Yes, we already received an approval for five samples for firearms application and just finished sampling for munition, hope this will also be approved in the following days and our R&D department is also communicating on new projects with other Polish customers.

MILMAG: All right. Thank you so much for the interview. It was a pleasure to learn so much about you and your company, and to be honest I wasn’t expecting such a company to exist in Slovakia and go into the military industry.

A.G.:: Thank you, it was a pleasure. I hope we’ll see some meetings in Poland in the future as well.

GEVORKYAN, a.s.is a company specializing in powder metallurgy, headquartered in Slovakia. Founded in 1996 as a greenfield project in Vlkanová near Banská Bystrica by its founder and current majority owner, Dipl. Ing. Artur Gevorkyan, a military aeronautical engineer originally from Armenia, the company has grown into a leading powder metallurgy plant in Europe. Bringing together four innovative technologies, in-house development, a state-of-the-art laboratory, and a precision tool shop under one roof, GEVORKYAN delivers over 100 million components annually to customers in more than 30 countries worldwide. For nearly three decades, the company has been a trusted partner, providing efficient, high-quality solutions across various industries – from automotive and energy to consumer goods and defense. True to its motto, “Your flexibility with our solutions,” GEVORKYAN doesn´t just manufacture products, it delivers tailored solutions that help customers succeed.