WB Group has already mastered the production process and is currently testing completed shells that have not yet been filled with high explosive (INERT). The Polish company has developed the production of shell bodies starting with the initial machining of steel forgings supplied by Polish steel mills.

155 mm artillery shell bodies presented by WB Group / Photos: Jakub Link-Lenczowski, MILMAG

As MILMAG’s editorial team has learned, an ammunition assembly and shell-filling (explosive loading) center operated by WB IM has been established in western Poland. Infrastructure covering 900 m² has been built on a 14-hectare site and will be expanded to include reinforced-concrete storage facilities protected by earth berms. This will make it possible to store large quantities of explosives as well as to manufacture and store completed shells.

This is the only entity within the WB Group holding the appropriate scope of licenses and infrastructure for both the production of artillery ammunition and warheads for WARMATE loitering munitions. As can be inferred, it may also possess capabilities to produce armament for future next-generation strike systems.

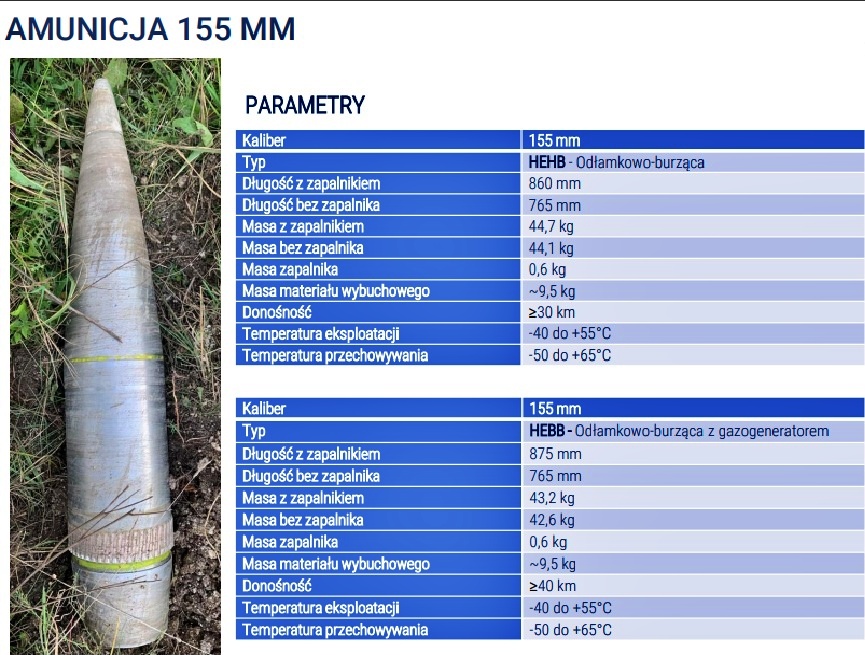

Ultimately, two types of shells are to be produced: HEHB (high-explosive fragmentation) and HEBB (high-explosive fragmentation with base bleed). As Piotr Wojciechowski explained, fuzes are purchased from an external supplier, while discussions are underway with two European suppliers regarding propellant charges. Base-bleed gas generators, meanwhile, have already been developed and tested on a test bench.

INERT shell during the tests and sample characteristics of the ammunition / Image: Grupa WB

The certification process is scheduled to be completed in September 2026, while 5,000–10,000 shells are to be produced over the course of that year. Full-scale serial production is planned to begin in 2027, with an expected output of between 50,000 and 100,000 shells annually.

Importantly, the first live-fire tests have already been conducted at a range of 17 km (outside Poland). According to President Wojciechowski, the operational system was used and the shells successfully passed pressure tests while achieving good accuracy on target. The next stage of testing will involve firing at a range of 40 km, which is planned for early next year.

Cross-section of the shell casing

President Wojciechowski also confirmed that the certification process is being conducted along two parallel tracks, in Poland and abroad. This means that WB Group will be able to offer its ammunition globally. Looking at the planned dates for the completion of certification and the start of serial production, it can be inferred that the entire process is aligned with the planned implementation schedule of the pan-European SAFE (Security Action for Europe) program (Polish Ministry of National Defence has submitted applications to the European Commission under the SAFE program).